4 结论

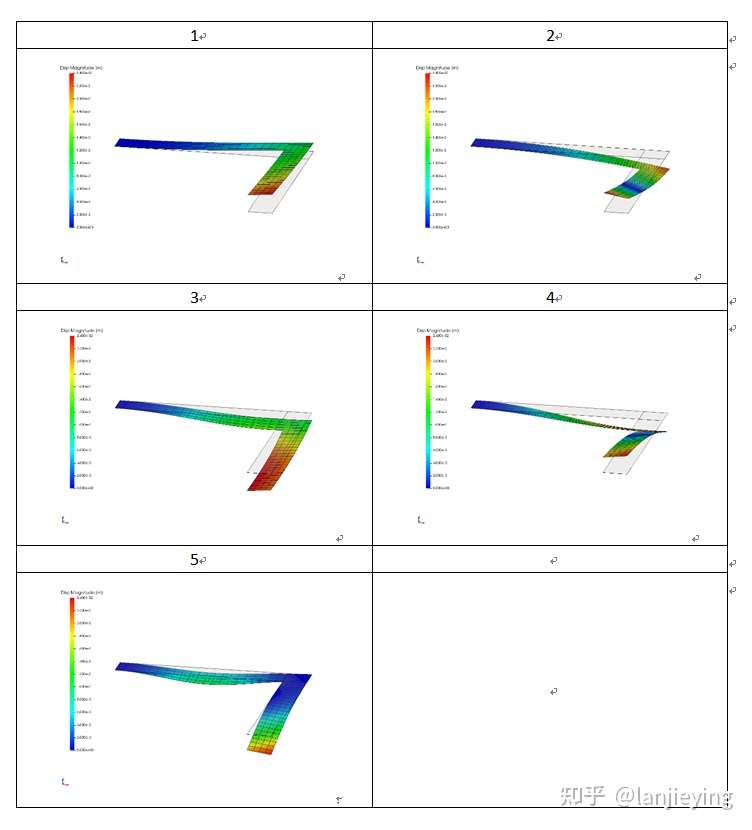

本文分析对比各种截面的加强筋结构对模态性能的影响,三角形截面的加强筋对结构的模态频率影响最大,梯形次之,矩形截面的加强效果最差;对与梯形截面来说,其上底边越短,加强效果越好,这说明从矩形截面到三角形截面的加强效果是逐步提高的。对于有大平面的电池托盘来说,横向加强筋能够有效地提高其一阶模态频率,但是纵向加强筋的增多反而会降低一阶模态频率,所以在设计此类托盘时,只需要一条纵向加强筋就可以了。最后,本文通过拓扑优化分析了此托盘加强筋的最优化分布,并结合制造工艺性和电池的安装要求选择了合适的加强筋结构和分布,达到了设计要求,为此类零件加强筋的设计和布置提供了方法和依据。

5 参考文献

[1]Altair HyperMesh .基础培训教程.上海:澳汰尔工程软件(上海)有限公司.2003

[2]张胜兰等.基于HyperWorks的结构优化设计技术.北京:机械工业出版社.2008

[3]张洪武等.有限元分析与CAE技术基础.北京:清华大学出版社.2004:95~136

[4]李楚琳.张胜兰等.HyperWorks 分析应用实例.北京:机械工业出版社.2008

Design and Optimization Method of Battery Tray of Hybrid Automotive

Li Zhixiang Mei Jifa Cao Lufen

Abstract: Adopting finite element method,this paper analyzes and compares the influence of four different types section shape on modal performance,and obtains common rules of the affection of different section shape. That provides instruction for design and optimization strength ribs for battery tray of a hybrid automotive. Using OptiStruct topography optimization,this paper optimizes distribution of refinement ribs with the load case combined with modal and -3g acceleration in Z direction. The optimized distribution of strength ribs is given. Finally, this paper accomplishes the design of strength ribs according to the manufacture process and performance requirement,proposes a method for design and optimization of this kind of battery tray.

Key words: Bttery Tray Constraint Modal Topography Optimization CAE OptiStruct