车门结构模态应错开载荷激振频率和整车频率。路面激励频率多出现在1-3Hz,因车轮不平衡引起的激励频率一般在1-30Hz,发动机引起的激振一般在23Hz以上。一般情况下,20Hz-30Hz是比较敏感频率区域,本模型第一阶模态频率为45.19Hz,成功避开了这个区域,仿真结果证明车门的自由模态满足要求。

5. 车门抗凹性能分析

若车辆外板件抗凹性不好,按压时会发生过大位移甚至凹坑,给顾客留下不好的印象。因此,车辆外板件的抗凹性能也是评价性能之一。对于前侧门而言,由于外板厚度为0.8mm,且表面光滑无特征,因此需要评价其抗凹形能。

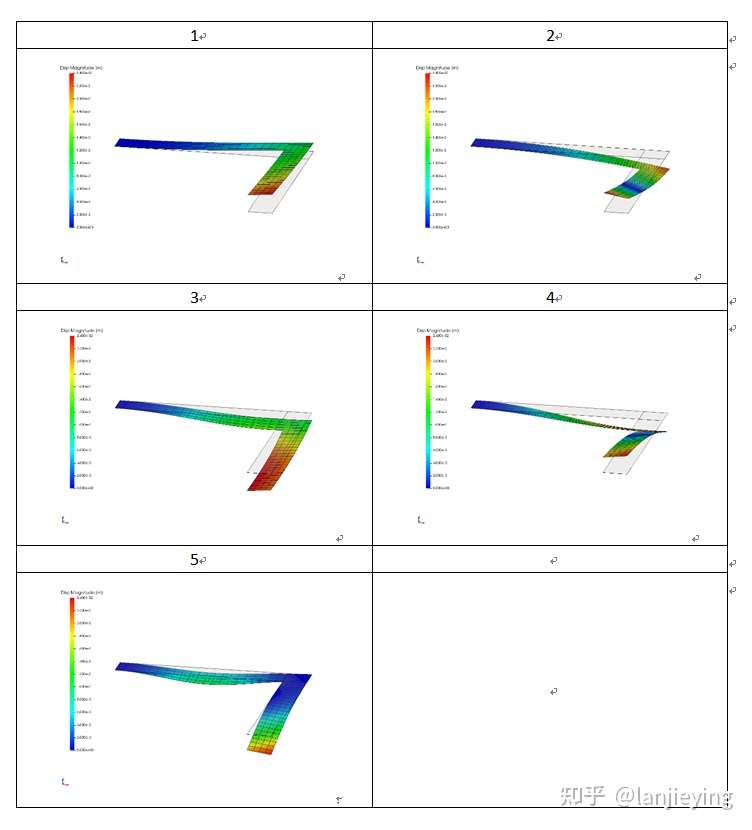

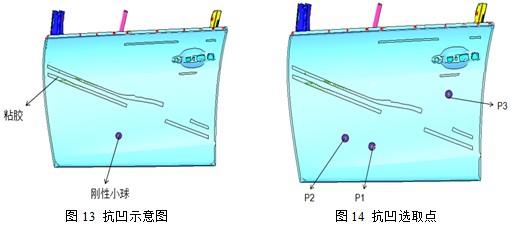

车门抗凹性能的模拟方法如图13所示:固定门边,建立一个直径为40mm的刚性小球,并给小球在门外板表面法线方向的10mm强制位移实现“按压过程”,以小球和外板之间的接触力为评价指标。

抗凹点的选取:一般在平缓无特征的区域,周围较大范围内无支撑。本车门模型选3个抗凹点,如图14所示。其中P1点为自由模态中外板局部模态的最大振幅点,P2点处于粘胶和下特征线的中央位置,P3点处于上特征线和粘胶的中央位置。

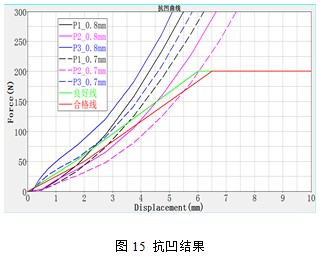

图15是本次抗凹分析的结果。P1_0.8mm表示外板为0.8mm时P1点的抗凹性能曲线,P1_0.7mm表示外板为0.7mm时P1点的抗凹性能曲线,其余类似。曲线在合格线上表示合格,在良好线上表示良好。从图中可以看出,外板为0.8mm时,P3点曲线基本处于良好线之上,此点抗凹形能良好。P1和P2点曲线部分处于合格线之下,即初始阶段不能满足要求。当外板为0.7mm时,3个点的抗凹性能均下降较多,且P2点严重不满足要求。由此可见外板厚度应为0.8毫米。

6.结论

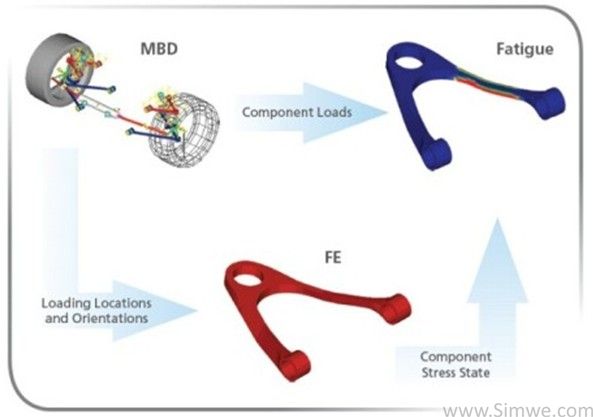

本文用有限元方法借助HyperMesh和RADIOSS模拟分析了某乘用车左前门的性能,包括刚度性能、模态性能和抗凹性性能,结果表明车门的刚度和模态性能满足公司标准,外板采用0.8毫米时车门的抗凹性能也基本满足要求。该车门的样车顺利通过了车门的疲劳试,验证明了仿真结果的可靠性。

7.参考文献

郝琪,张继伟.基于数值模拟的轿车车门静态性能综合评价及模态分析.机械设计与制造,2008,11.

李楚琳,张胜兰,冯樱等. HyperWorks 分析应用实例. 北京:机械工业出版社. 2008.

Junbo Jia,Anders Ulfvarson A parametric study for the structural behaviour of a lightweight deck.Engineering Structures,2004,26:963-977

J.K.Shin, K.H.Lee, S.I.Song, et al. Automotive Door Design with the ULSAB Concept using Structural Optimization. Struct Multidisc Optim, 23: 320-327

胡朝晖,成艾国,王国春,钟志华.多学科优化设计在拼焊板车门轻量化中的应用.中国机械工程,2010,21(4):495-499

德安,赵建才.轿车车门刚度有限元分析及结构优化.汽车工程,2001,23(6):47-51

RADIOSS Application in Performance Simulation of Car Door

Shi Shaoliang, Zeng Ji , Wu Fei

HNU College of Mechanical and Vehicle Engineering, State Key Laboratory of Advanced Design and Manufacture for Vehicle Body, Hunan University

Abstract: Stiffness, free modal and dent resistance are the most three performance in the car door performance simulation. The gap between the door and the frame and the deviation control are affected by the door performance. The fatigue life of the body parts are also affected. The sealing performance of the doors are also affected, even lead to the window frames rattling in the glass lift or cannot lift

The performance simulation of a car door was completed in this paper, used by HyperMesh and RADIOSS. The simulation performance of the door were compared with the standard of the company. The result showed that the performance of the door are good enough. The cars with the door passed the fatigue test, which proved the reliability of the simulation.

Key words: Door Stiffness Free Modal Dent Resistance RADIOSS