3右悬置动刚度敏感性分析

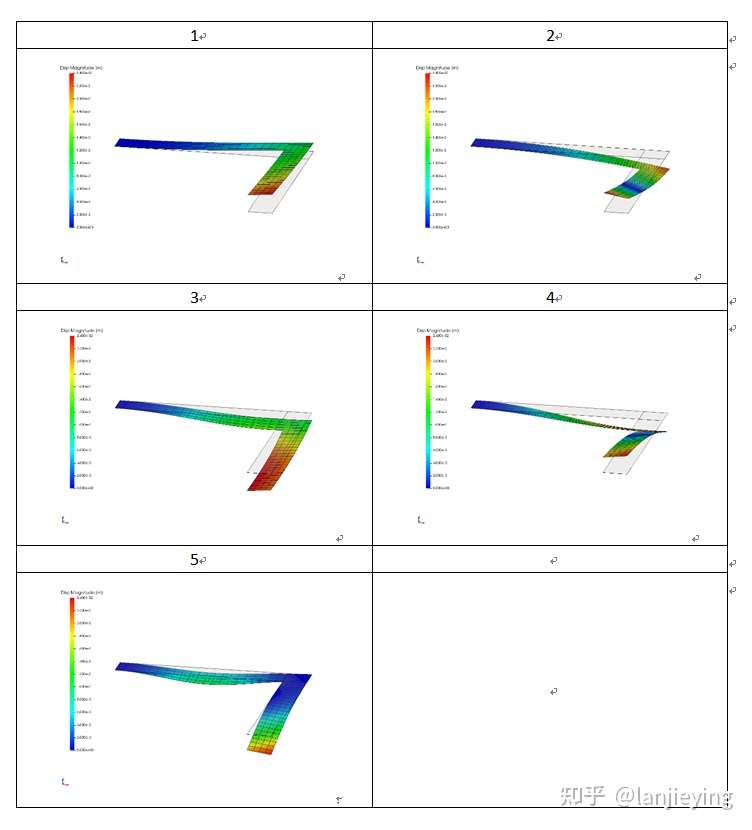

为了提高右悬置Z向的动刚度。本文基于原方案对Z向动刚度进行结构参数敏感性分析,结果如图6所示,由图可知,方案5满足动刚度要求。基于方案5,并考虑装车工艺对右悬置进行动刚度分析,结果如图7所示。方案f05满足动刚度要求,同时也考虑了装配与焊接工艺等因素,是一个可行的方案。

4试验验证右悬置优化方案

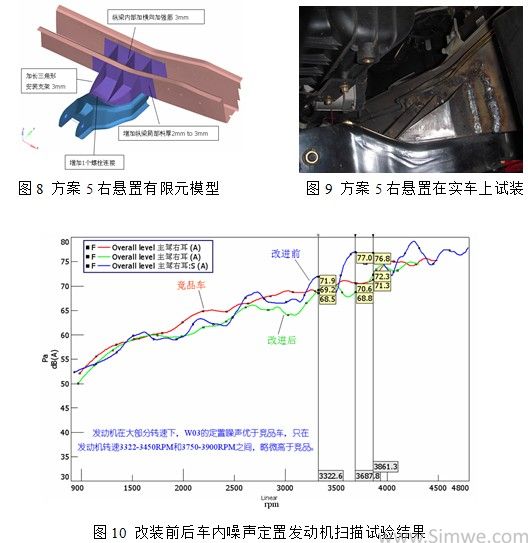

方案f05对应的右悬置有限元模型如图8所示。方案f05实车安装如图9所示。

将麦克风置于驾驶员右耳的位置,定置发动机扫描车内噪声试验结果如图10所示。试验结果表明在发动机转速为2000rpm以前,改装前后车内噪声差别不大,从2000rpm到4400rpm,改装后车内噪声明显有改善。其中在发动机转速为3315rpm时车内噪声降了4.3dB,3671rpm时降了10dB,3860rpm时降了4.5dB。车身抖动亦有明显的减弱。采用改进方案后,该微型车在行驶过程中车内噪声和振动主观感觉亦有明显改善。

5结论

本文采用Altair HyperWorks软件对某微型车右悬置车身端支架进行模态分析,对右悬置模型进行动刚度分析。基于仿真分析结果,最终提出右悬置优化方案。车内噪声测试结果表明该优化方案能够有效改善车内噪声,验证了仿真分析及优化方案的有效性。

1.有限元分析技术能有效的分析结构各个参数对设计方案的影响,并且能通过优化技术得到较优的合理解决方案。

2.基于动力总成悬置系统刚度匹配原则优化右悬置模型动刚度,能有效改善车内噪声。

3.将微型客车改装成方案f05后,发动机在3315rpm时车内噪声降了4.3dB,3671rpm时降了10dB,3860rpm时降

4.5dB,解决了该车型在3000rpm到4000rpm的噪声问题。

6参考文献

[1]张立军,靳晓雄,余卓,平周铉.轿车车内噪声控制方法研究[ J]. 汽车工程,2002,24(1):15-19

[2] Rong Guo, Shan Qiu, Qin-lin Yu, Hong Zhou and Li-jun Zhang.Transfer path analysis and control of vehicle structure-borne noise induced by the powertrain[C]. Journal of Automobile Engineering,2012,

[3] Norbert W. Alt, Norbert Wiehagen and Michael W. Schlitzer. Interior Noise Simulation for Improved Vehicle Sound[ C]. Society of Automotive Engineers, Inc. 2001-01-1539

[4] 庞剑,谌刚,何华.汽车噪声与振动理论与应用[ M] .北京: 北京理工大学出版社, 2006

Research on Reducing Interior Noise Based on the Analysis of Engine Mounting Dynamic Stiffness

Chen Xiu Tan Wei Wang Yan Kou Yuqiao

Abstract: Resonate sound and serious body vibration occurred when engine work with high speed in process of moving. The NVH test results show that the right engine mount bracket do not have enough dynamic stiffness in Z direction. Altair HyperWorks was used to calculate the right engine mount dynamic stiffness. A more reasonable scheme was found based on stiffness matching principle of the powertrain mounting system and result of structure parameter sensitivity analysis also taking factors such as assembly and welding process into account. NVH test results show that Interior Noise was significantly reduced with 4.3dB drop at engine speed of 3315rpm and10dB drop at engine speed of 3671rpm, 4.5dB drop at engine speed of 3860rpm.The body vibration subjective feeling also significantly weakened.

Key words: Interior Noise HyperWorks Dynamic Stiffness Sensitive Analysis